Frequently Asked Questions

Where are you sourcing lumber from?

We offer kiln dried flat sawn lumber from New York City and surrounding areas. These trees are removed or naturally fall every day, the primary reasons being: storm damage, safety hazards, pest infection, or to make way for urban expansion. These fallen trees are routinely wasted by either burning, chipping or being dumped in a landfill. At the same time, local woodworkers are habitually paying a premium for hardwoods at lumber retailers which come from all over the country an often from healthy trees harvested just for lumber. Our process eliminates sourcing healthy trees for lumber.

If the tree shows signs of damage - will this effect the lumber in my piece?

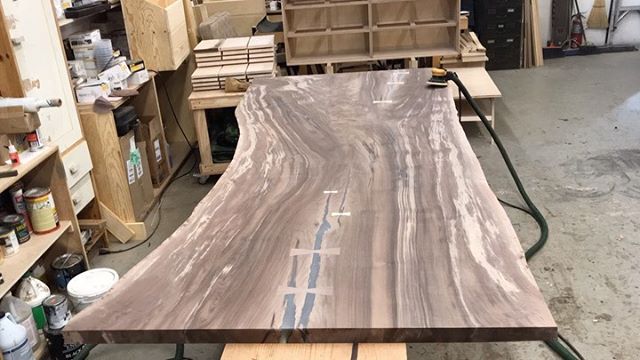

Only in a positive way! We find that markings like spalting (from fungus) or ambrosia (from bugs), are often the most cherished characteristics in a slab. Cracks and knots are opportunities for creative intervention, like butterflies to bridge a split or resin to solidify imperfections without losing sight of them. These are optional upgrades which we will recommend if needed.

Spalted Beach with stabilizing bowtie and resin filling.

Maple with ambrosia - also known as “wormy maple”.

Can you remove trees from my property?

We work with local arborists who can provide you a quote for tree removal. Our stockroom is presently full so we are not taking new logs at this time.

Do you sell rough sawn slabs to woodworkers?

Our Ridgewood workshop doubles as a showroom. We have slabs in the rough on site available for purchase as is. You can view our inventory here.

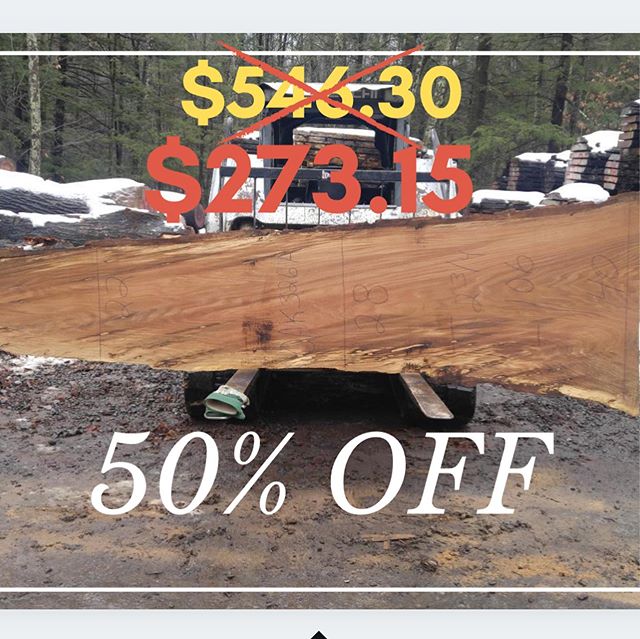

What are the letters and numbers on your slabs?

We run our logs through the mill to create a “flitch”, or a series of slabs from the same tree. The flitch gets a unique code and the individual slabs are labeled with a corresponding letter, for example A is from the top of the stack and typically has a steep slant to the edge, whereas slab D might be from the center of the tree, making it wider than A and having a fairly straight edge.

Our slab room.

Drying flitch - A through F.

What is the drying process?

When we get a log, even from a dead tree, it still retains a lot of moisture. Once it is cut into a flitch, we let it air-dry in our upstate yard for 2 years before putting it in our kiln. This is to keep the slab as flat as possible. Drying it too fast in a hot environment is like throwing bacon into a pan - it creates unwanted cupping and warps.

How long is production on a custom slab project?

Typical production time is 6-8 weeks. When a slab comes out of the kiln, even after all that air-drying, it is rarely dead flat. When we flatten the slab to remove any imperfections, it opens up the pores of the wood leaving it vulnerable to cupping and warping. To avoid this we’ve developed a 2 week clamping system that prevents warps after the slab has been flattened.

I live outside of NYC, can I still purchase from you?

Our products have found homes throughout the US. Our design team will work with you remotely to talk you through options and decisions. We can provide shipping and freight quotes by request on furniture or rough sawn slabs.

Have another question?